Lettuce

H2-A is Only Legal Solution For Labor Without Immigration Reform

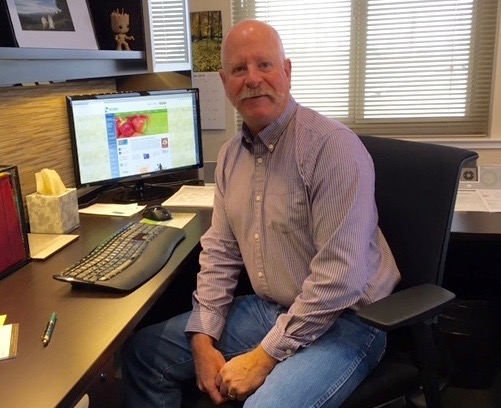

H2-A is Heart of One Farm Labor Contractor

By Patrick Cavanaugh, Editor

H2-A employees are the heart of one major farm labor company. Steve Scaroni owns Fresh Harvest, a premier labor provider and staffing and harvesting company to the agricultural industry and the western United States. But the company’s main emphasis has always harvested crops related to salads; they have also expanded into permanent crops.

“Last year, we started citrus and pears, and we will continue to expand in vegetables with anything that goes into a salad, lots of head lettuce, romaine, and broccoli, which is what we have been doing for a long time,” Scaroni said.

And then we touch a lot of salads every day. The H2-A temporary agricultural program allows agricultural employers when anticipating a shortage in domestic workers to bring non-migrant foreign workers to the US to perform agricultural services for a temporary or seasonal nature.

“If it wasn’t for H2-A, I wouldn’t be in business. I mean that’s the only way to get a legal worker into California to serve my customers demands for the services we offer, which is mostly labor and harvesting,” Scaroni said.

“And we’re even starting to do a lot of farm services. We’re bringing up 100 irrigators this year to put throughout the Salinas Valley because our Salinas customers can’t get enough irrigators,” he said.

Being a labor contractor has its difficulties. It takes a lot of work. It’s a very bureaucratic process-driven application process.

“Laborers that show great work ethic will be able to work for a longer period of time. A worker could technically stay if I can move it from contract to contract, and I can keep the temporary employee for three years,” Scaroni said. “But then he has to go back for 90 days, but it’s very hard to time the contracts for that to work.”

“So most guys, they’ll do five, six, seven months. They’ll go home before they can come back. And then the guys that are really good workers with and a great attitude and really get it done for us. We’ll move to another contract. Will even retrain them in a different crop if they have the right attitude and work ethic,” he said.