Lettuce

New UCCE Advisors Bring Fresh Ideas to Protect Lettuce From INSV, Pythium Wilt

By Mike Hsu, UCANR

Salinas Valley lettuce growers lost about $150 million in 2022 due to diseases

A stormy winter could portend another devastating year for the lettuce industry in the Salinas Valley, which saw approximately $150 million in lost gross revenue in 2022 due to INSV (impatiens necrotic spot virus) and associated diseases. Recent drenching rains might mean more weeds – overwintering “reservoirs” for the tiny insect, the Western flower thrips, that carries INSV.

Or the extreme precipitation could benefit growers, as thrips in the soil – during their intermediate stage of development – might be drowned in the waterlogged fields.

As with so many aspects of the INSV crisis, the ultimate effects of flooded fields on thrips populations remain unknown.

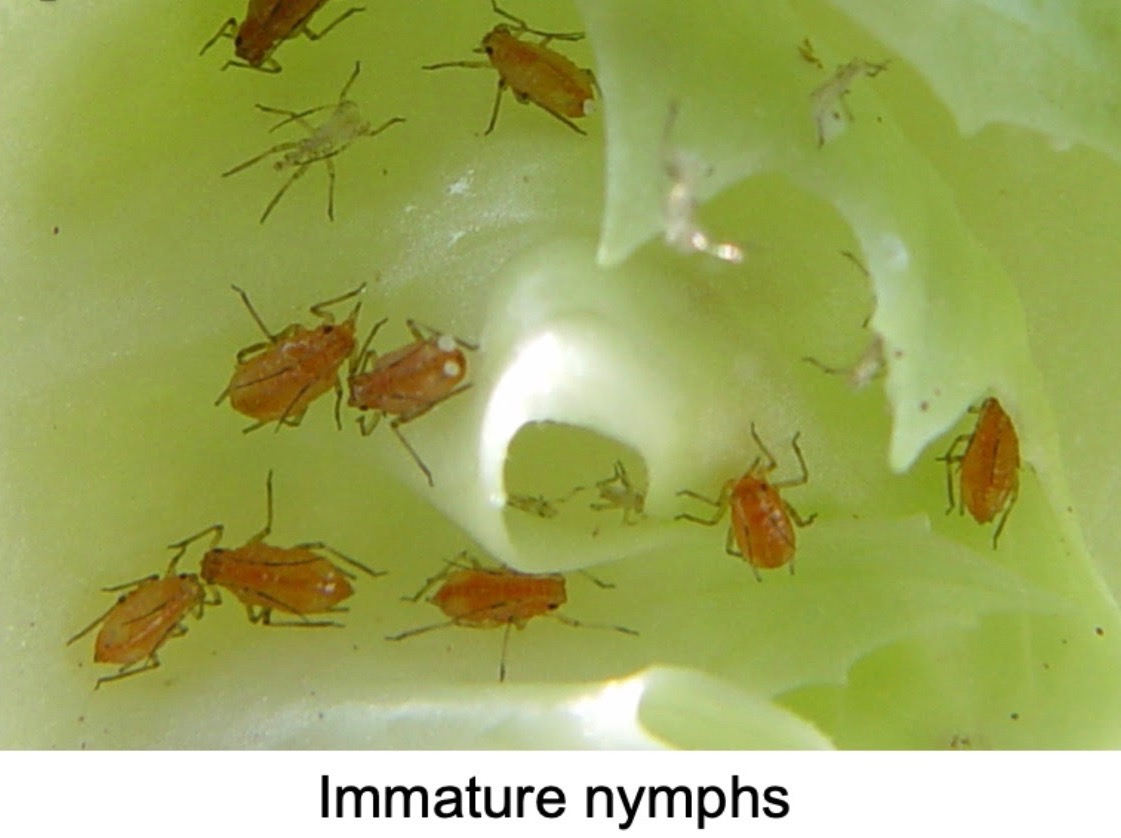

“We don’t know if thrips are just so persistent and so stable in that pupal stage that maybe they will emerge unaffected,” said Kirsten Pearsons, University of California Cooperative Extension integrated pest management farm advisor for Santa Cruz, Monterey and San Benito counties. “There’s just so much about their biology and ecology in the Salinas Valley that we just don’t know.”

The mystery of thrips, INSV and soilborne diseases (namely Pythium wilt) is why UC Agriculture and Natural Resources assigned Pearsons to the area last November and hired Yu-Chen Wang in October as UCCE plant pathology advisor for the three counties.

“They’re stepping in at a critical moment,” said Richard Smith, the region’s UCCE vegetable crop production and weed science advisor who retired in January after a 37-year career. “They’ve gotten grants funded already – and that’s just incredible. They’re hitting the ground running.”

Experienced in disease diagnosis and collaboration with growers and industry partners, Wang said her pathology background – paired with Pearsons’ entomology expertise – will be crucial in addressing INSV and other diseases.

“It is important for Kirsten and me to work together and provide different insights for the vector and the pathogen, respectively,” Wang said.

‘It’s going to take everything to get a crop’

One priority is untangling the dynamics of INSV and Pythium wilt co-occurrence – the subject of ongoing research by JP Dundore-Arias, a plant pathologist at California State University, Monterey Bay. While the vegetables may tolerate one disease or the other, their one-two punch often deals the lethal blow.

“The challenge is – which is why it’s great to have Yu-Chen and Kirsten – is that we have so many problems now, whether it’s Fusarium (wilt), or Verticillium (wilt), or Pythium, or INSV,” said Mark Mason, pest control adviser for Nature’s Reward, which primarily grows lettuces on 5,000 acres across the Salinas Valley.

Mason said that co-infections on his crops (sometimes with three or four diagnosed diseases) make it difficult to assign monetary damages to a specific pathogen, but he noted he has seen fields with “100% loss.” According to the Grower-Shipper Association of Central California, about 11,500 acres were deemed not harvestable in 2022, representing 12% of lettuce industry acreage.

Given the gravity and complexity of the disease dilemma, Pearsons said she has been fielding calls from growers seeking new and better solutions – ways to improve existing tools, techniques borrowed from other crop systems, and additional biological or chemical means of control.

And although there are a couple of pesticides that manage the disease-carrying thrips reasonably well, growers and researchers are worried about their diminishing efficacy due to overuse. Plus, they only constitute a short-term fix.

“Managing the thrips will only reduce the amount of INSV that can get transmitted,” Pearsons explained. “You can kill 99.9% of the thrips, but you get one thrips that has INSV that enters a field, and now you have an infected lettuce plant. All of the thrips are going to come and they can spread it from there; pesticide slows things down, but it’s not going to eliminate it.”

Finding disease-tolerant lettuce cultivars is a more sustainable approach. Trials conducted last year by Smith, Wang and others identified several varieties that appeared to hold up well to Pythium and INSV. While additional research could maximize their potential benefit, Wang said even the hardier cultivars will lose their resistance over time, and a multi-layered INSV strategy with “integrated management tools” is crucial.

“We realized, when this thing started happening, that we cannot spray our way out of this problem,” Mason said. “We need varieties; we need management practices; we need pesticides…it just seems like it’s going to take everything to get a crop.”

Weeds key to disease control

An all-hands-on-deck approach helped control thrips-harboring weeds last winter. With fields drying out from January storms, Smith said communities must get back to weed management – with a focus on prominent weed hosts for INSV and neglected areas adjacent to farms. Hotspots of infection last year were traced to industrial lots that were overlooked during the weeding process.

“People can’t lose sight of the fact that we still need to be controlling the weeds in key areas, because that’s the reservoir of the virus during the winter,” Smith said. “We have to stay on task with that.”

Yet despite the diligent weed abatement, crop damage from INSV and Pythium was widespread in 2022, and Smith said it’s “very possible” that high heat during the summer was a contributing factor to especially prevalent disease in fall. Thrips populations tend to thrive in warmer weather, Smith said, but much more research needs to be done to understand the basic biology of the insect, including how they acquire the virus and how they spread it.

High hopes for future

Pearsons cited the work of Daniel Hasegawa, a research entomologist with the U.S. Department of Agriculture, who leads teams in monitoring thrips populations in several locations across the Salinas Valley. Currently the counting of thrips on sticky card traps is done manually, but Pearsons and Mason mentioned the possibility of using AI and machine learning to expedite that process.

Mason said that the grower community is excited about the new technologies and ideas that Pearsons and Wang are bringing to the region. As a participant in the search for candidates to fill the advisor positions, Mason said “they were, in my opinion, by far the best fit for what we were looking for.”

“I hope they stay here for 30 years,” he added.

The new advisors both noted the palpable energy and cooperative spirit in the Salinas Valley to proactively meet the challenge.

“Looking to the past, there have been other outbreaks and diseases that they’ve managed to overcome,” Pearsons said. “These farmers are resilient and creative and I fully believe that lettuce will still be growing here for years to come – it might look a little different, and it might take a little bit of a painful period to get to that point, but I think that we’re going to be able to come up with some solutions.”

And while there are concerns that some lettuce growers might decide to leave the region, Wang said she also believes in the industry’s strong roots and rich history.

“Salinas Valley has had a beautiful climate for lettuce for so many years; there are some undeniable advantages here,” she said. “This is still the best place in the United States – and maybe the world – to grow lettuce.”